As a leading brand leading the development of the zipper industry, Kee has been committed to the research and innovation of zipper technology. We have a highly sophisticated and professional R&D team dedicated to achieving innovative breakthroughs in new material applications, process improvements, and functional design. After continuous efforts and exploration, we successfully launched Notape's century-old zipper innovation. It removes the tapes on both sides, making the production process simpler and the clothing more integrated, beautiful and smooth!

We always uphold our passion for technological innovation, constantly challenge ourselves, and are committed to creating more competitive and forward-looking product solutions. In the future, we will continue to increase investment in research and development, continue to delve into the field of zipper technology innovation, and inject new vitality and power into the development of the industry.

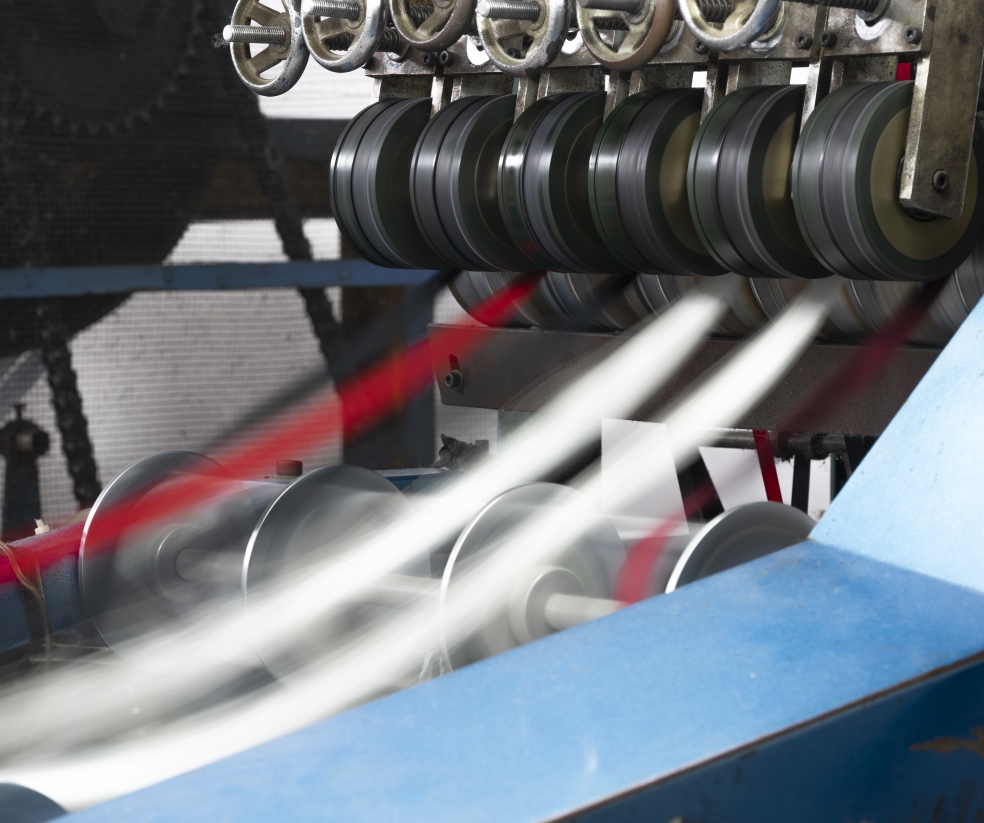

Our vertically integrated zipper production capabilities span across textile, chemical, precision mold, hardware, stamping, die-casting, injection molding, electronics, machinery, and other industries. We specialize in custom design, manufacturing, and fulfilling various orders for customers. Throughout the production process, we enforce rigorous quality control on each key production stage.

Kee is committed to providing sustained quality zippers to our valuable customers. Quality is our primary focus, while a sustainable quality control is the way we follow.

-Most equipments are tailored and self-developed.

-A majority of production implement automatically.

-Production is continuously streamlined, including process reengineering and optimization.

-Higher standards are applied than industry.

-The own lab allows most of the physical and chemical tests to be done in-house.

-Well trained QC specialists, advanced apparatus and rigorous process are in place.

-Full scale QC progress covers IQC, OQC and in-progress inspection.

KEE continuously works and improves quality craftsmanship. KEE is conforms to global standards by various certifications.

We have independently developed a range of production equipment, such as fully automatic dyeing tape wrapping machines, metal zipper dyeing machines, nylon zipper ultrasonic punching machines, and zipper cutting machines.

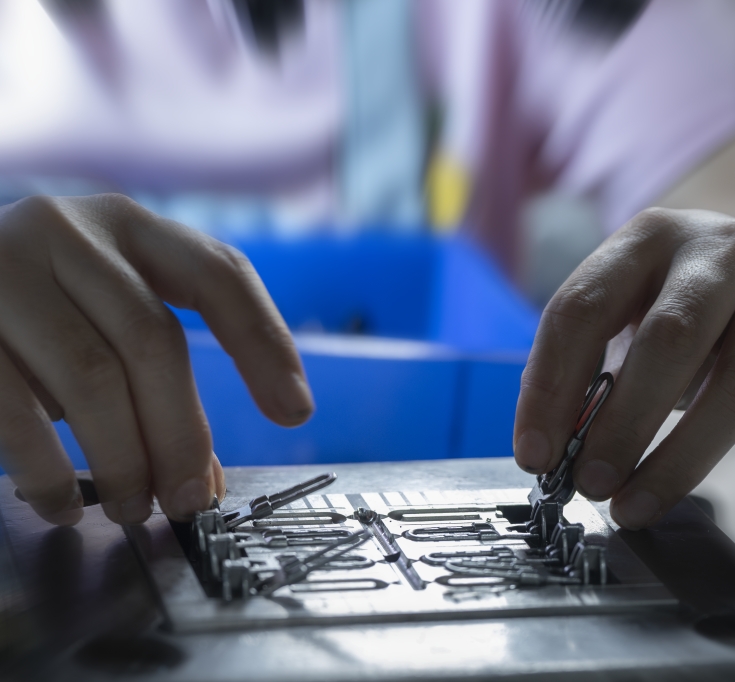

Based on customer needs and market trends, the team designs zipper products, including determining the shape, function, material, etc.

Raw materials are processed and assembled on the production line, including sprocket tooth forming, slider installation, zipper sheet production, etc., to ensure that product quality meets standards.

The quality inspection department conducts strict quality inspection on the zipper products produced to ensure that the products meet customer requirements and standards.

After the finished product is packaged, it is ready to be delivered to the customer, including labeling, packaging, storage and other links to ensure that the product is safely delivered to the customer.

Kee provides after-sales service to ensure customer satisfaction and collect product usage feedback.